Carbon fibre - a modders guide

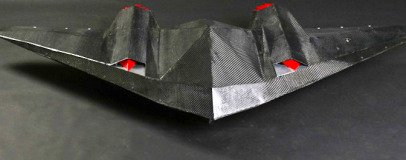

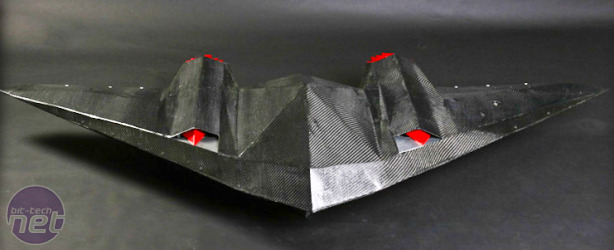

As materials go, carbon fibre isn't something you'd associate with anything other than a Formula One racing team, or a supercar. However, we've seen a couple of modders incorporate it into their builds over the years (craigbru's OSIDIAS springs to mind), and they're not just using this fancy material for the odd detail either. Forum user Cleveland216, aka Dave Biro, has recently completed a simply stunning tribute to advanced aircraft design using only carbon fibre to construct the outer shell of the case, with an aluminium core.

Click to enlarge

Called SSR-X, it's a stunning project that branches PC modding out into yet another area of expertise. We'll hopefully hear from Dave on SSR-X in more detail soon in a full article, but for now, we've been discussing carbon fibre, and its uses in PC modding.

bit-tech: What materials other than carbon fibre have you worked with?

Dave: In my ten years of modding I have worked with an extensive variety of raw materials. I started out with steel and stainless steel. The stainless steel was 304 grade, tough stuff! I was getting the material for free from scrap piles at work because I had little money at the time. I worked with cheap Plexiglass in the early days, before I would eventually come across cast-cell acrylic. In the 2010 Aelro build I used 6061 Aluminium sheet and Cast-Cell acrylic. By the end of the build, I worked with the three primarily materials used in the modding community. Time to really venture into something new and quite yet not fully explored.

bit-tech: Is carbon fibre difficult to work with compared to say aluminium or acrylic?

Dave: Don't make a mistake! Throwing a piece away is costly. Use a mask, work gloves, and eye protection. I have heard of health hazards. Carbon fibre creates a lot of dust that doesn't smell good and will turn skin black if it's exposed while cutting and drilling with it. My fingers and hands were black for weeks. Carbon fibre edges are extremely sharp and splinters will be common, if you do not wear gloves. I also spent time picking pieces of carbon fibre out of my hands. The actual workability depends on the formation process of a carbon fibre piece.

Click to enlarge

If the process didn't go well, than the piece could have a flaw that you don't know about until you start cutting and drilling. Make sure you got a good solid part. I highly recommend using a fibre cutting wheel to get a clean cut on carbon fibre. I don't recommend a tooth-edge blade because it will create a jagged splintery edge. Carbon fibre drills real easy. One can also heat up a completed carbon fibre piece to bend it. The piece should be held in its final position until it fully cools or it will re-bend back into its original shape. Weird, but awesome! Carbon fibre is also water-proof. Water will bead right off it.

bit-tech: What drew you to it as a material to make a scratchbuilt PC?

Dave: There are several factors here: First being that I was inspired by Craigbru's Osidias build. Second that the production processes for carbon fibre have not yet all been used in demonstration with case mod building i.e. vacuum resin infusion, and third a large carbon fibre case build has never been attempted. Beyond those three factors there are the lightweight and strength properties along with the fabric's look.

bit-tech: Did you have any previous experience using it?

Dave: A complete carbon fibre virgin!

bit-tech: Is it expensive to use?

Dave: Yes compared to other raw material cost. The way one will produce a carbon fibre part is the main determiner for the overall cost. Keep in mind that depending on what process you use it determine the quality of your part. The cheaper the process the crappier the part will be typically in terms of its properties.

A. Open-air lamination is the cheapest because it just uses fabric and resin.

B. Vacuum bagging is the second costly because now one needs a vacuum pump, vacuum bagging material, fabric, and specialty resin, along with minor other various components like seal tape. A mould may or may not be required for this process.

C. Vacuum resin infusion is the greatest in cost besides autoclaving! Resin infusion requires a mould, very specific purpose resin, and a greater number of component parts to complete the process, i.e. flow lines, infusion connectors, gel coat, reinforcement coat.

Click to enlarge

The fabric weave will vary the price. Typical 2x2 CF twill will cost $30/yard. A yard being 60” wide by 36” length. I purchased mine on eBay in bulk for $25/yard due to the bulk purchase. Than there is the resin! This once again depends on the process one will use to make the carbon fibre part. There are a variety of Resin kits that can be anywhere from ~$100 per kit to above $1000.

Little component pieces can nickel and dime you to death and will added up in the end to make the overall process even more expensive.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.